The global market for cellulose powder is rapidly expanding, driven by demand across diverse industries. From food and pharmaceuticals to textiles and construction, cellulose powder's unique properties make it an crucial ingredient. To navigate this complex landscape, it is critical to understand the key players shaping the cellulose powder market. This guide seeks to provide a comprehensive overview of prominent cellulose powder manufacturers worldwide, highlighting their expertise and influence.

- Additionally, this guide will explore the newest trends influencing the cellulose powder industry, such as sustainable manufacturing practices and innovative applications.

- By providing insights into the global landscape of cellulose powder manufacturers, this guide aims to equip businesses with the understanding they need to make wise decisions.

Prominent Cellulose Powder Manufacturers in India

India's thriving production sector relies heavily on reliable cellulose powder suppliers. Numerous firms are dedicated to producing and distributing this essential material across diverse fields.

Some of the most respected cellulose powder manufacturers in India include:

- Producer C

- Producer F

- Manufacturer H

These companies are known for their focus to quality, innovation, and environmentally-friendly practices.

Seeking Your Premium Cellulose Powder?

You've arrived at the perfect location! We specialize in providing remarkable quality cellulose powder, carefully obtained from trusted suppliers. Our cellulose powder is highly-regarded for its consistency, making it the optimal choice for a wide range of applications, including development.

Whether you're in need of cellulose powder for industrial purposes, our team is committed to satisfying your expectations.

- Investigate our comprehensive selection of cellulose powder types and grades.

- Experience our competitive pricing and prompt shipping options.

- Reach out our knowledgeable experts to discuss your specific requirements.

Delving into the Cellulose Powder Manufacturing Process

The manufacturing process for cellulose powder involves a series of meticulous steps to transform raw plant materials into a versatile, powdery substance.

Typically, cellulose powder use the process begins with the procurement of suitable raw fibers, which are then treated to remove impurities and enhance their cellulose content.

Subsequently, the purified cellulose undergoes a physical pulverization process, resulting in fine particles of cellulose powder. This powder can be further processed through various techniques to achieve specific properties and uses.

- Fundamental processes in the cellulose powder manufacturing process include:

- Fiber extraction

- Moisture removal

- Grinding

- Inspection

The resulting cellulose powder finds wide deployment in various industries, including textiles, pharmaceuticals, food additives, and biofuels. Its adaptability and inherent eco-friendliness make it a valuable material for numerous technological advancements.

From Wood Pulp to Powder: The Science of Cellulose Production

Cellulose, a fundamental macromolecule, constitutes the primary structural component of plant cell walls. Derivation of cellulose from its natural sources, predominantly wood pulp, involves several intricate stages. Initially, wood undergoes mechanical grinding to liberate the cellulose fibers. These fibers are then subjected to a chemical process employing solutions like sodium hydroxide or sodium sulfite to dissolve lignin, a complex substance that binds cellulose together. The resulting slurry containing purified cellulose is further refined through washing and bleaching procedures.

To obtain cellulose powder, the purified pulp undergoes a evaporation process, transforming it into a fine, white powder. This cellulose powder can then be used in various applications, including the production of textiles, paper, biofuels, and cosmetics.

Fine-Tuning Cellulose Powder Manufacturing for Efficiency and Quality

The creation of cellulose powder presents a unique set of difficulties. To ensure both efficiency, manufacturers must utilize strategies that maximize yield while maintaining the highest quality of cellulose. This involves careful evaluation of factors such as raw material procurement, processing parameters, and monitoring systems throughout the production line.

- Enhancing the extraction process can significantly boost cellulose yield, while minimizing byproducts.

- Implementing advanced drying techniques helps to maintain the quality of the cellulose powder.

- Regulation of process parameters ensures consistent product quality and eliminates batch-to-batch difference.

Additionally, investing in automation can streamline production processes, leading to increased capacity. By continuously monitoring and refining manufacturing practices, producers can achieve a greater level of efficiency and product quality in cellulose powder production.

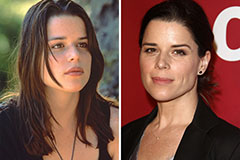

Neve Campbell Then & Now!

Neve Campbell Then & Now! Shaun Weiss Then & Now!

Shaun Weiss Then & Now! Molly Ringwald Then & Now!

Molly Ringwald Then & Now! Susan Dey Then & Now!

Susan Dey Then & Now! Erika Eleniak Then & Now!

Erika Eleniak Then & Now!